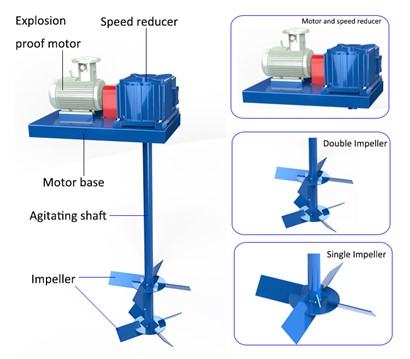

Agitator

MileZagros agitators are employed in mining and refining projects. Advances in impeller technology and design techniques have improved the performance and efficiency of our agitators and the leaching process overall while reducing the loading of the agitator drive assembly and associated structures. Attention to details such as particle size, density, flow rate and sparge requirements to ensure the process is met; finally, the mechanical integrity of the agitator components and drive system are designed and selected to ensure our agitators are both economical and robust. Retrofitting and Refurbishment of existing agitators produces not only power savings but also increases the operational life. MileZagros offers full technical and maintenance support to all sites with our efficient after-sales service. It is our priority to ensure we are available for site visits, installation inspections and hot/cold commissioning services.

AGITATOR REQUIREMENTS

As a manufacturer of heavy-duty agitators and associated services in the mining and refining industry, we pride ourselves on high quality, reliable designs and manufacturing capabilities. Each agitator is custom designed for your specific requirements by highly trained design engineers.

The mining industry has many varied process conditions and agitators seldom have to perform only one simple duty. Agitators for Mining applications are often combinations of:

- – Solids Suspension

- – Blending / High Tank Turnovers

- – Conditioning

- – Attritioning

- – Heat Transfer

- – Mass Transfer

- – Adsorption

- – Leaching

- – Repulping

- – Head Generation

One of the most common applications in the mineral processing industry is the suspension of solids. Grind size, material density, product viscosity and throughput; all play their part in agitator designs. The efficiency of the agitators are also greatly influenced by the type of impeller selected. These factors combined with the operating condition, such as start-up in settled solids and varying liquid levels are examined by experienced MileZagros Applications Engineers to ensure the customer receives the best possible agitator for the duty specified.